Everything freezes after the M03 command. SheetCam TNG v 4.0.10 Mach3 v R3.043.022 But in the last 48 hours I am at my wits end. Still using my original versions of Sheetcam and Mach 3. All in all, I’ve always been able to get the job done. In order for the path rule to be used, it must be selected in the operation in sheetcam. I have run my plasma CNC about 5 years, nursing dry air issues along the way. The idea is they turn the torch height control off at certain points to prevent it from diving, or slow down the feedrate for corners to prevent rounding. plasma, laser, water etc.) then select Jet cutting. If you have a jet cutter of some sort (i.e. We recommend it for PlasmaCutting, since it has all the settings/inputs you need for proper plasma cutting. If you have a milling machine or router select Rotary cutting.

SheetCam is suitable for milling, routing, plasma, waterjet, laser and oxy-fuel cutting. In there select the path rules tab and you can edit those rules parameters for your liking. SheetCam is a low cost but feature packed CAM package. Rules to prevent diving (Turn THC Off) and Rounded Corners:

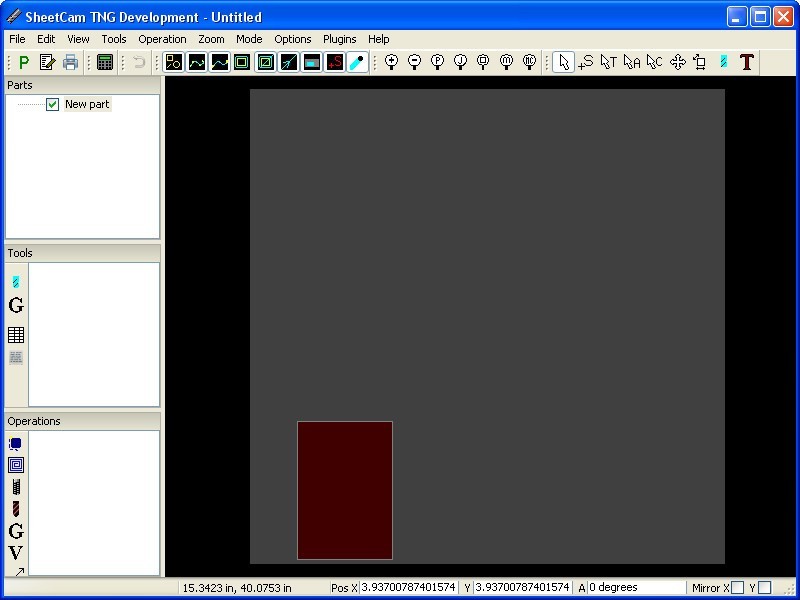

#Sheetcam plasma setup code#

Set the Code Name and enter the filename of the code to run in the box below, without the extension:.Under tools menu option, click the G code option.We recommend it for PlasmaCutting, since it has all the settings/inputs you need for proper plasma cutting. The code in this file simply toggles the state of the THC button on the plasma screen, effectively turning THC control on and off. SheetCam is a low cost but feature packed CAM package. Weve created a template for the most common materials and the settings you will need to cut using the Hypertherm plasma cutters.

If M244 already exists in your directly, change the attached file name to an available number and use that new number for the rest of the setup where we have 244. Torch height has the greatest affect on bevel angle of the plasma cut piece. MACHINE TORCH SETUP powermax105 Operator Manual. Each voltage setting corresponds to a specific height that optimizes the arc characteristics for a clean, straight cut.

0 kommentar(er)

0 kommentar(er)